Using technology to support Infrastructure Asset Management strategies

Written by Dan Patterson, Product Strategy at BKwai

The Situation

Infrastructure Asset maintenance is a key part of the bigger asset management discipline. Determining appropriate response(s) to asset degradation helps to uphold the financial and service value of a physical asset.

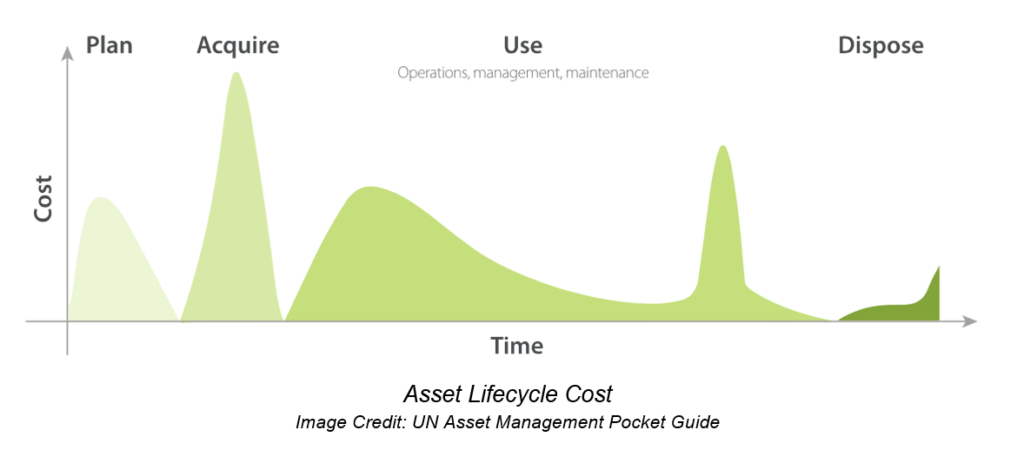

An asset undergoes a life cycle that typically is represented through 4 stages – planning, acquisition, use and disposal. Each of these phases carry a cost as the example below shows.

There are well established disciplines to help forecast and manage these cost phases including project planning for “plan”, construction management for “acquire” and maintenance management for “use” and decommissioning for “dispose”. Solutions like that from BKwai fall into the discipline of maintenance management to support the “use” phase of the asset lifecycle. The use phase is typically not only the longest phase but also incurs the most cost as well. Understanding these two variables is key to successful asset management.

The Inevitable Asset Deterioration Curve

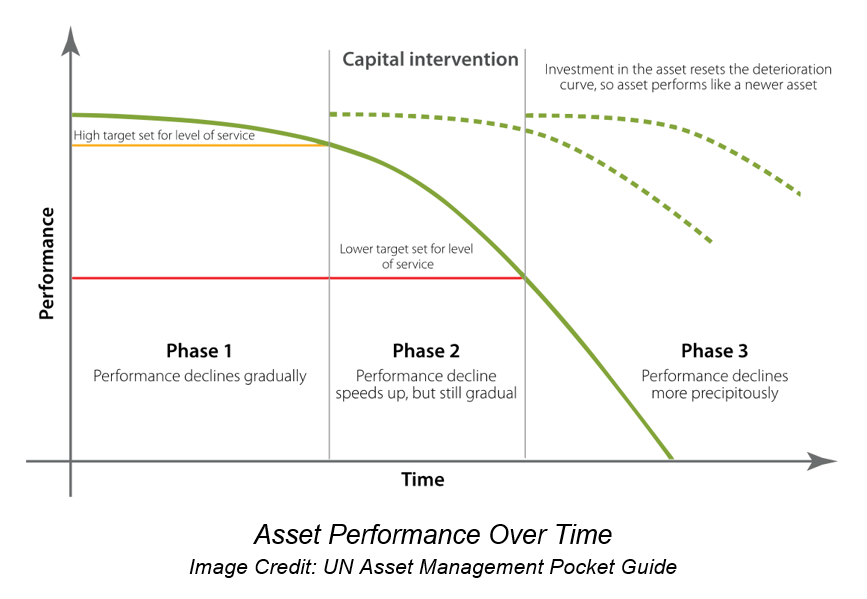

All assets deteriorate over time. The rate of deterioration is dependent on many influencers including:

- Design characteristics of the asset

- Environmental influencers e.g. normal weather patterns, soil conditions

- Discrete events e.g. earthquake

- Activity e.g. traffic patterns

These all impact the speed at which an asset deteriorates.

Likewise, the rate of asset deterioration can be slowed down by maintenance intervention – this requires investment. Understanding how much investment and when such investment should be applied is a difficult determination for asset owners to make given the uncertainty pertaining to the true future impact of the asset influencers. In summary, how do we achieve an appropriate mix of interventions in context of influencers?

Types of Intervention/Maintenance

Maintenance strategies can be classified into three categories:

- Preventative – pro-active investment in scheduled maintenance activities resulting in reduction or even avoidance of degradation

- Corrective – repairs to defects of minor impact after they occur

- Reactive – response to a major defect after the fact

Corrective maintenance typically carries a 5x cost multiplier compared to an ongoing preventative maintenance schedule. Worse: a reactive response can be as much as 25 times that of a preventative maintenance plan. So why would an organization ever not pursue a preventative maintenance plan? The answer is boils down to the balance of risk-reward. The greater the forecast time window, the harder it is to predict an asset’s behaviour and how it will actually respond to it’s influencers e.g. in 5 years from now, what will be the vertical movement on a pier? This makes the true determination of risk very hard to accurately predict.

If asset owners had greater visibility into the future state of their investments as well as a greater degree of confidence that the predicted state is indeed accurate, then the challenge of determining how much preventative maintenance spend becomes much more straightforward.

Using Data Science to supplement decision making

Using a predictive engine powered by data science algorithms allows us to forecast future state, by analyzing historical trends and extrapolating these forwards to generate a predicted state at a given point in time. Achieving an accurate forecast can be complex depending on the number of as well as the magnitude of, external influencers e.g. weather.

The more influencer dimensions available to the engine, the higher degree of certainty can be assumed from the model. Today, amongst other factors, weather and temperature influences help to better normalize forecasts.

By understanding the impact of preventative maintenance and comparing this to a strategy that rests its outcome on hoping corrective action isn’t required, we can easily calculate the ROI of these two strategies. From this, an informed decision can be made as to which strategy is most cost-effective.

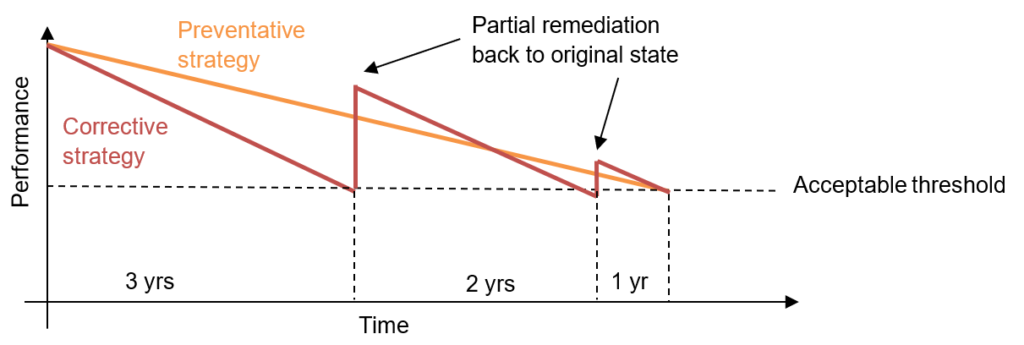

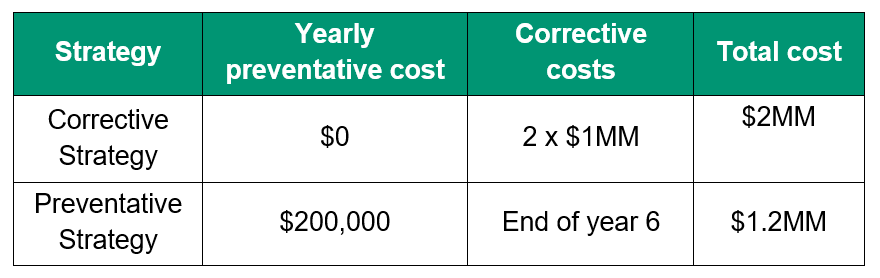

Consider two simple scenarios: the preventative maintenance strategy and the corrective maintenance strategy.

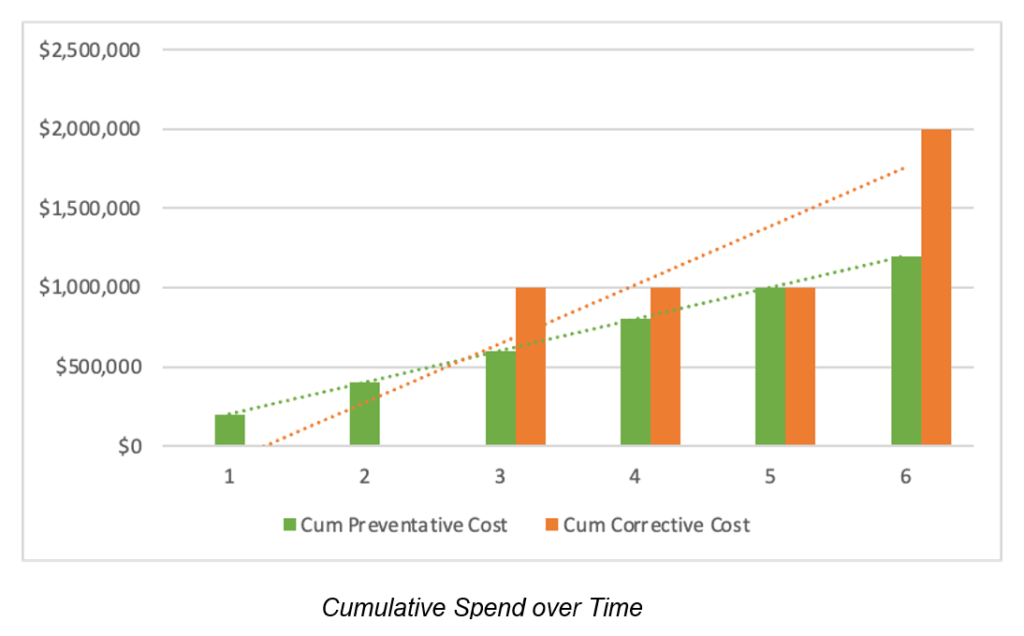

In the example above, both strategies give us a 6-year asset life. So which strategy should we adopt?

Example Simple Cost Comparison Between Corrective and Preventative Maintenance

Both strategies result in the same lifespan but the preventative strategy is $800K cheaper and results in better cashflow after year 3.

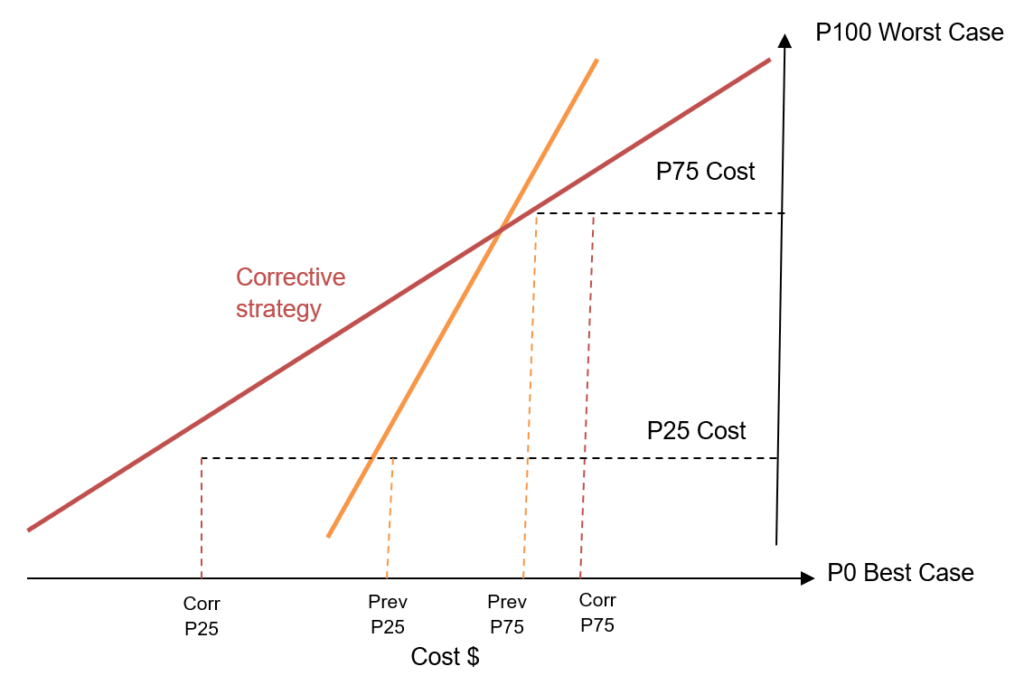

These simple models can be even more valuable when we add the dimension of certainty (or conversely, risk) to the equation. By modelling certainty of factors such as spend, effectiveness of corrective and preventative work on the performance of the asset, we can then start to report in context of certainty as well. For example, a typical organization will make decisions within the context of a given confidence or P value. Outcomes from different maintenance strategies will vary depending on the P-value adopted.

In the example above, a risk adverse organization (one that adopts a high certainty outcome e.g. P75) is better off adopting a preventative maintenance strategy (from a cost perspective).

Conversely, a more risk tolerant organization (willing to adopt a lower confidence of success e.g. P25) is better off adopting the corrective strategy.

Having such insight into alternate scenarios and outcomes is something that is very difficult to effectively achieve on paper or even in XLS-based models.

This is where products like that from BKwai’s enable the merging of historical trend interrogation and predictive analytics to deliver powerful decision support to asset owners and operators.

To find out how BKwai can enable you to make smarter decisions please contact us